Name:HB series speed reducer industrial mill reducer

Models:HR27,HR37,HR47,HR57,HR67,HR77,HR87,HR97,HR107,HR137,HR147,HR167,

The input power, allowed torque&weight list of HRX reducer

Installation

Elasic coupling, tooth coupling or ather non=rigid coupling shall be used to connect a reducer with a motor and warking machine, The

installation deviation of the reducer shall not be more than the permitted balue of the coupling used. After installing, commissioning and aligning a reducer, you must fix the foot bolts firmly on the foundation or base frame, The reducer shall be so installed that after the installation, the input shaft can rotate smoothly but not seize when one rotates it by hand.

Lubrication

There are two lubricating ways, i. e oil-bath and circulation one. For a teducer working in a high ambient temperature. with high power and speed or working continuously one shall use circulation lubrication as far as possible, so as to reduce oil temperature and give full play to the bearing capability of the reducer.

We produce reducers by assuming oil-bath lubrication way,if you need circulation lubrication, you can modify and supplement that by yourself or specify that at ordering so that we can provide oil-circulation cooling unit When the reducer's working ambient temperature is low, one make measures to maintain the oil temperature to be more than 0 ºC.For selecting one shall select the make of middle extreme-pressure industrial gear oil(GB5903-86 )according to the input shaft speed,input power and gear ratio etc.

The oil lebel in the oil bath shall be so that when the reducer stops the oil level control is at a point a little higher than the center of the

two graduations of oil labeler.

Interval for replacing lube for a new reducer(or a newly-replaced gear), replace lube once after running 10-15 days. Under a normal case,for a reducer running continuously 24 h/day, replace lube once in less than 3 months For a reducer running less than 10 h/day, replace lube once in less than 6 months.

When a reducer stops successively for more than 24 houts, it shall first tun at dry load when restarting, and can tun under load onliy when the gear and bearing are fully lubricated.

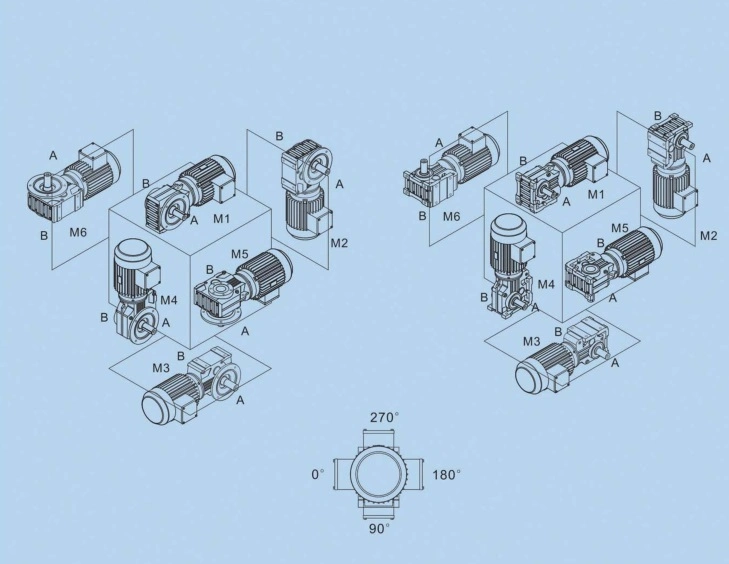

Mounting Poisition and motor terminal box position of HR reducer

Models:HR27,HR37,HR47,HR57,HR67,HR77,HR87,HR97,HR107,HR137,HR147,HR167,

The input power, allowed torque&weight list of HRX reducer

| Model | 57 | 67 | 77 | 87 | 97 | 107 |

| Structure | HRX,HRXF/HRX&HRXF | |||||

| KW/input power | 0.12-7.5 | 0.12-7.5 | 1.1-15 | 1.5-22 | 5.5-45 | 5.5-45 |

| Transmission ratio | 1.31-5.47 | 1.43-5.92 | 1.41-5.69 | 1.35-6.25 | 1.40-5.75 | 1.43-6.71 |

| Nm/allowed torque | 59 | 114 | 180 | 340 | 505 | 705 |

| Kg/weight | 9.6 | 15.4 | 25.3 | 42.9 | 77 | 110 |

| Model | 27 | 37 | 47 | 57 | 67 | 77 |

| Structure | HR,HR..F,HRF | |||||

| KW/input power | 0.12-3 | 0.12-3 | 1.12-5.5 | 0.12-7.5 | 0.12-7.5 | 0.18-11 |

| Transmission ratio | 3.37-136 | 3.4-133.3 | 3.87-182.6 | 4.32-183.2 | 4.32-180.7 | 5.28-200.9 |

| Nm/allowed torque | 110 | 170 | 255 | 380 | 510 | 700 |

| Kg/weight | 6.2 | 9.4 | 11 | 20 | 28 | 40 |

| Model | 87 | 97 | 107 | 137 | 147 | 167 |

| Structure | HR,HR..F,HRF | |||||

| KW/input power | 0.55-22 | 0.55-37 | 2.2-55 | 5.5-75 | 11-110 | 11-160 |

| Transmission ratio | 5.33-245.7 | 4.52-280.6 | 4.98-255.4 | 5.22-223.2 | 4.93-162.1 | 10.43-224.6 |

| Nm/allowed torque | 1320 | 2550 | 3670 | 6800 | 11050 | 15300 |

| Kg/weight | 70 | 112 | 169 | 245 | 440 | 770 |

Installation

Elasic coupling, tooth coupling or ather non=rigid coupling shall be used to connect a reducer with a motor and warking machine, The

installation deviation of the reducer shall not be more than the permitted balue of the coupling used. After installing, commissioning and aligning a reducer, you must fix the foot bolts firmly on the foundation or base frame, The reducer shall be so installed that after the installation, the input shaft can rotate smoothly but not seize when one rotates it by hand.

Lubrication

There are two lubricating ways, i. e oil-bath and circulation one. For a teducer working in a high ambient temperature. with high power and speed or working continuously one shall use circulation lubrication as far as possible, so as to reduce oil temperature and give full play to the bearing capability of the reducer.

We produce reducers by assuming oil-bath lubrication way,if you need circulation lubrication, you can modify and supplement that by yourself or specify that at ordering so that we can provide oil-circulation cooling unit When the reducer's working ambient temperature is low, one make measures to maintain the oil temperature to be more than 0 ºC.For selecting one shall select the make of middle extreme-pressure industrial gear oil(GB5903-86 )according to the input shaft speed,input power and gear ratio etc.

The oil lebel in the oil bath shall be so that when the reducer stops the oil level control is at a point a little higher than the center of the

two graduations of oil labeler.

Interval for replacing lube for a new reducer(or a newly-replaced gear), replace lube once after running 10-15 days. Under a normal case,for a reducer running continuously 24 h/day, replace lube once in less than 3 months For a reducer running less than 10 h/day, replace lube once in less than 6 months.

When a reducer stops successively for more than 24 houts, it shall first tun at dry load when restarting, and can tun under load onliy when the gear and bearing are fully lubricated.

Mounting Poisition and motor terminal box position of HR reducer